ANSWERS FOR TODAY. INSIGHTS FOR TOMORROW.

The world is changed. The global energy transition is impacting equipment operations, engineering practices, and inspection strategies across all industrial processing industries.

As operations evolve, we know how important it is to remain aligned with your company’s long-term strategic direction, achieve proactive asset management, and meet jurisdictional requirements. At E2G | The Equity Engineering Group, Inc., our consulting services, corporate standards, and industry-leading software deliver practical solutions that solve your asset challenges and meet your operational needs.

What are you looking for?

FFS

Training

RBI

3% Rule

Software

Practices

Fitness-for-Service

Deteriorating assets, including fixed equipment, structures, foundations, and other infrastructure, cost businesses billions of dollars per year. Assessing the integrity of your in-service equipment will help you proactively solve issues, minimize failures, and save money…

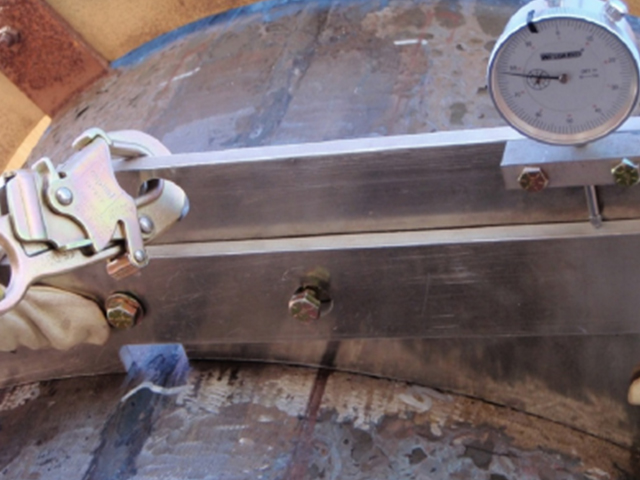

Fitness-for-Service for Aboveground Storage Tanks – Industry Insights

The 5th edition of ANSI/API 2530 Overfill Prevention for Storage Tanks in Petroleum Facilities was published in September 2020. The revision was informed by regulatory concerns over several incidents of gross overfilling leading to serious consequences affecting employees and nearby communities. All incidents can be traced to loss of operational control of storage tanks, chiefly during filling activities…

E2G Event Calendar

Quickly access upcoming virtual or in-person training courses, webinars, and other E2G-hosted events. Our monthly webinars are complimentary and include a variety of industry-relevant topics. All API-U and E2G Technical Institute (ETI) training courses can be customized to meet your organization’s training needs and qualify as activities for API’s CPD requirements.

API-U Approved Training

We believe in continuous learning for both you and your team. As active participants in the American Petroleum Institute (API) and the American Society of Mechanical Engineers (ASME) committees, we stay on top of industry technology, standards, and advancements. We use this knowledge to develop high-quality training courses and webinars to help fuel your curiosity of the processing and manufacturing industries…

Risk-Based Inspection

Risk-based inspection (RBI) quantifies risk and gives you the wisdom to make informed decisions about how, where, and when to inspect assets. Remove uncertainty by evaluating your equipment and refocusing inspection efforts onto the highest-risk items…READ MORE >

Storage Tank RBI

It’s costly and time- consuming to inspect storage tanks. Many facilities apply risk-based inspection (RBI) techniques to defer these costly internal inspections that were scheduled using a time-based interval…READ MORE >

API RBI Software

Many companies provide RBI (Risk-Based Inspection) software. Most claim to be compliant with API RP (Recommended Practice) 580; a few claim to comply with API RP 581. E2G |The Equity Engineering Group, Inc.’s software is the only API-branded RBI software product because we are committed to fully supporting the RBI technology as documented in API RP 581…READ MORE >

Inlet Pressure Drop

Recent changes to the infamous 3% rule on inlet pressure drop to pressure relief valves (PRVs) have raised many questions. The ongoing efforts by the API improve the current industry codes and standards for pressure relief valve instability…

Pressure Relief Systems – Everything You Wanted to Know

Pressure relief systems (PRS) are used at thousands, if not millions, of refineries, petrochemical plants, and other industrial processing facilities around the world. Properly functioning relief systems are essential for protecting plant personnel and equipment from unexpected overpressure events which may result in equipment damage, loss of containment, environmental damage, costly plant shutdowns, and/or non-compliance fines…

SagePlus Software

Achieve safer facilities and plants by evaluating equipment design and in-service conditions to make informed engineering decisions on the remaining life of fixed equipment, piping, and structures…

API RBI Software

Many companies provide RBI (Risk-Based Inspection) software. Most claim to be compliant with API RP (Recommended Practice) 580; a few claim to comply with API RP 581. E2G |The Equity Engineering Group, Inc.’s software is the only API-branded RBI software product because we are committed to fully supporting the RBI technology as documented in API RP 581…

DamageWeb

Proactively understand the maze of damage mechanisms found in your facility and select the best inspection method for each type of damage to reduce costly fixed equipment failures and increase operational safety. DamageWeb, a cloud-based tool, is the only software created to specifically help inspection and maintenance personnel streamline the process of pinpointing damage mechanisms and identifying potential risk areas…

Engineering Practices (EEPs)

Where are the Corporate Standards? Or maybe the question is more often “When were the standards last updated?” Do either of these questions sound familiar? Now it’s possible for all employees – from engineering to the plant – to easily access current, searchable, and customized corporate standards from design to replacement. There is only one solution that delivers…

How Do Your Standards Compare?

Corporate Standards are essential for sharing knowledge throughout your company. Having up-to-date and easily accessible standards ensures your facilities and equipment are operating both safely and reliably. Take this quick test to find out how your organization’s engineering standards compare to the industry’s most comprehensive best practices…

Your Organization and Industry Have Specific Needs…So Stop Settling for Generic Best Practices!

What differentiates the EEPs from other solutions is that the system, its delivery method, and all of its contents are fully customizable. Each organization is provided with their own branded and customized version of our most current base collection delivered through an access-controlled website. As part of the initial and on-going customization effort, we work with organizations to incorporate corporate preferences, corporate memory, and lessons-learned into their customized collection…

Industries We Work With

We take a multi-disciplinary approach to help you improve facility-wide safety, increase inspection efficiencies, reduce equipment downtime, and maximize operational reliability.

Oil & Gas

Address the evolving needs in the upstream and downstream energy industries with E2G’s extensive engineering experience and software.

Midstream

Maintain the safety and integrity of aboveground storage tanks, terminals, and pipelines with proactive engineering services.

Chemicals & Petrochemicals

Minimize hazards and improve operational safety processing polymers, petrochemicals, and other feedstocks.

Nitrogen & Fertilizers

Control inspection costs, minimize corrosion or HTHA concerns, and improve reliability to meet the growing global demand for fertilizers and potash.

Renewables & Alternative Energy

Join the energy transition by shifting to sustainable production and operations while balancing operational reliability.

Other Industries

Manage risk, control inspection costs, and create safe operating environments at all types of industrial processing facilities, including nuclear energy, pharmaceuticals, and aerospace.

Events & Training

Calendar of Events

S Sun

M Mon

T Tue

W Wed

T Thu

F Fri

S Sat

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

1 event,

Storage Tanks

1 event,

1 event,

0 events,

0 events,

0 events,

0 events,

0 events,

0 events,

1 event,

Understanding Fertilizer Industry Damage Mechanisms: Failure Analyses and Case Studies

Understanding Fertilizer Industry Damage Mechanisms: Failure Analyses and Case Studies

This webinar will provide insight on common fertilizer industry damage mechanisms. Specifically, the importance and benefits of performing failure analysis whenever unexpected damage occurs will be discussed. Key considerations regarding […]

0 events,

0 events,

0 events,

1 event,

SagePlus/PlantManager with FFS Applications

0 events,

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

- There are no events on this day.

How We Can Help You

E2G takes a multi-disciplinary approach to solving your typical industry challenges. See below for how we can help solve three of the top challenges our clients experience.

Eliminate Knowledge Gaps

We’re in the midst of a massive crew change – subject matter experts (SMEs) are retiring, and there are fewer new engineers or personnel available to fill those roles. The Equity Engineering Practices (EEPs) capture SME knowledge and integrate that information into the industry’s most comprehensive corporate standards. The EEPs are accessible to all employees, which increases the safety and reliability of your facility.

Comply with Jurisdictional Codes & Regulations

Jurisdictional requirements change quickly, and non-compliance can result in costly fines or loss of revenue. As active members on many API and ASME committees, we know the codes and standards and use this knowledge on every project and technology we deliver. We help you meet jurisdictional requirements without over-engineering.

Minimize Unplanned Maintenance or Shutdown

All unplanned maintenance or shutdowns come with a significant cost – you need to get the equipment operating quickly to minimize production and revenue losses. E2G offers pre-turnaround planning, proactive fitness-for-service (FFS) assessments, and risk-based inspection (RBI) program implementation to help you minimize unplanned shutdowns, improve equipment reliability, and reduce operational risk.

Equity Engineering Practices

The Equity Engineering Practices (EEPs) are a collection of detailed and customizable Best Practices integrated with a management system provided to satisfy the requirements of Process Safety Management (PSM). Originally developed over two decades ago, the EEPs have been used on countless capital and maintenance projects across multiple industry segments and have been continuously updated and expanded to align with changing Recommended and Generally Accepted Good Engineering Practices (RAGAGEP) requirements.

Bring EEPs to Your Organization

This month’s articles discuss the complexities, challenges, and the strategies employed to ensure optimal performance and longevity of SMR units. In our first article, read about pressure swing adsorbers (PSAs) and share how a robust lifecycle management plan can improve reliability and extend equipment life. The second article highlights the necessity of separate Fitness-for-Service (FFS) studies for critical components like reformer heaters, providing a deeper understanding of proactive maintenance and risk mitigation strategies.

PSA on PSA Reliability

Authors: Neal Wagner, Staff Engineer II & Kate Gustoff, Consulting Engineer I

Learn how pressure swing adsorbers (PSAs) are crucial yet challenging in gas separation, and how a comprehensive lifecycle management plan based on engineering and fitness-for-service (FFS) can enhance reliability and extend equipment life. In this article, Neal and Kate discuss the importance of remaining life and inspection optimization studies in managing severe cyclic fatigue service, highlighting how pre-emptive fatigue studies guide inspection plans for PSA vessels. You will learn about inspection strategies and how to maximize capital investments through engineering strategies.

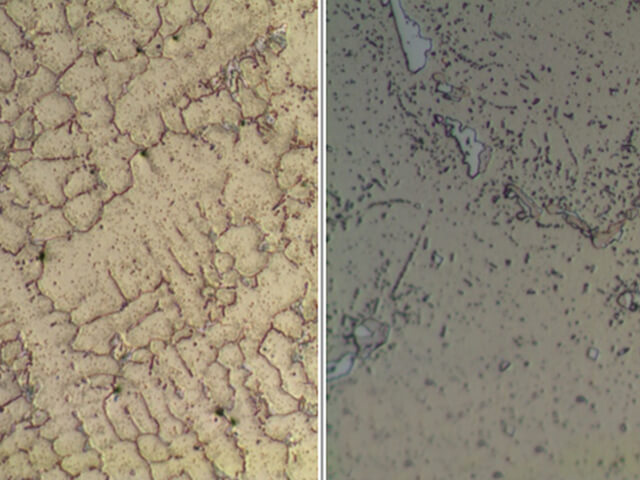

Understanding Damage Mechanisms in Industrial Gas Applications

Author: Phillip Prueter, Principal Engineer II

Metallurgy and corrosion experts a key to identifying damage mechanisms and predicting corrosion rates for equipment used in processes like steam methane reformers (SMRs) and air separation units (ASUs). In this article, you’ll read how important it is to recognize which damage mechanism can be reasonably captured with risk-based inspection (RBI) methods and which ones require more detailed analysis using FFS principles. In addition, you will also gain insights into how to create robust mechanical integrity programs for industrial gas production units.

Receive Industry Insights Articles in Your Inbox

About Us

E2G | The Equity Engineering Group, Inc. is a technology-driven company that solves engineering problems. Our consulting services and software are focused on finding answers to challenging industry problems, while promoting safety and reducing risk to people, equipment, and the environment.

E2G leverages technology and industry experience to extend the safe operating life of new and aging equipment by helping to prevent future failures, increase efficiencies, reduce downtime, maximize reliability, and minimize damage. We help clients improve profitability by managing risk and controlling inspection costs throughout a facility’s lifecycle.