Explainable AI: The Smart Solution for Industrial Safety

Explainable AI (XAI) is transforming infrastructure maintenance and saving millions

Solve CUI with Equity Research’s patent-pending AI workflow. Using all your data, Equity Research’s methodology will save you millions of dollars in inspection and maintenance costs plus reduce the risk of CUI damage.

What is Explainable AI?

Traditional AI is an amazing pattern finder. It can look at mountains of data, tell you what might happen, but it can’t explain the “why”.

Explainable AI or XAI is built completely differently - it's designed to understand cause and effect. Beyond predicting that a piece of equipment will fail, it also explains why it's going to fail.

XAI predicts what it thinks will happen based on physics, chemistry, and asset data. Next, it observes what's happening in the field, if there's a difference, the model will learn and update its own understanding. Finally, using the new smarter model it will recommend the best actions to take. XAI gets smarter with every piece of new information.

Download August Meeting Content

Join the Early Adopter Community

Sign up today and solve CUI once and for all.

Reduce CUI Leaks – prioritize CUI CML inspection plans

Save Millions – optimize maintenance & inspection costs

Improve Predictions – make full use of all data to improve predictions

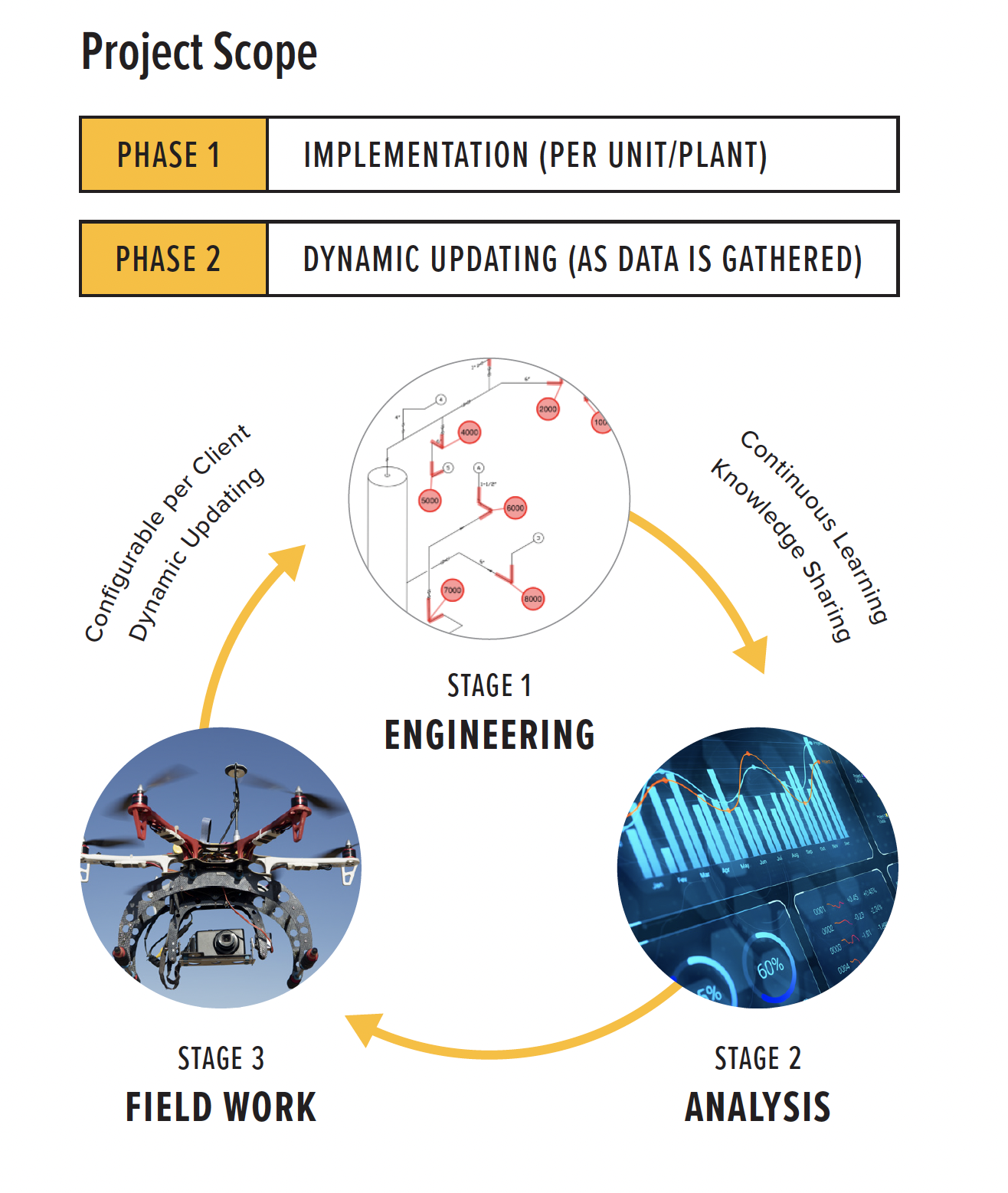

Solution: CUI as a Service

As an early adopter, you will join a pilot program that offers proactive and strategic recommendations for continuous CUI management. You will achieve improved predictions and get a handle on CUI, once and for all.

Step 1: Engineering

Step 2: Analysis

Step 3: Field Work

Case Study: Validate and Predict Future CUI Damage in Process Units

Industry: Midstream

Location: Middle East

Type of Asset: 50-Year-Old Plant (piping and cold insulation system design)

Issue: Minimal prior inspection and maintenance due to continuous operations, dozens of leaks in the past 10 years, and severe insulation system damage. CUI was getting out of hand with ineffective corporate CUI guidelines in place.

Solution: As shown by the validation data, Equity Research predicted all of the 42 cases with sufficient data available for model calibration and validation.

Result: Equity Research leveraged the calibrated and validated model to deliver a prioritized inspection plan for the unit that would have prevented 20 leaks ($20 million savings) and reduced excess inspections via focused NDE ($18 million savings).

Who is Equity?

At Equity, we are problem solvers.

We are focused on the safe and reliable operations of industrial equipment. We look at the whole picture and develop solutions that are purpose-fit for your unique needs. We are unified, collaborative, and proactive.

We are Equity.

© 2025 Equity Technology Group, Inc.

Equity Technology Group, Inc. is certified to the ISO 9001:2015 quality standard by ASR.